Keeping you and those close to you safe....

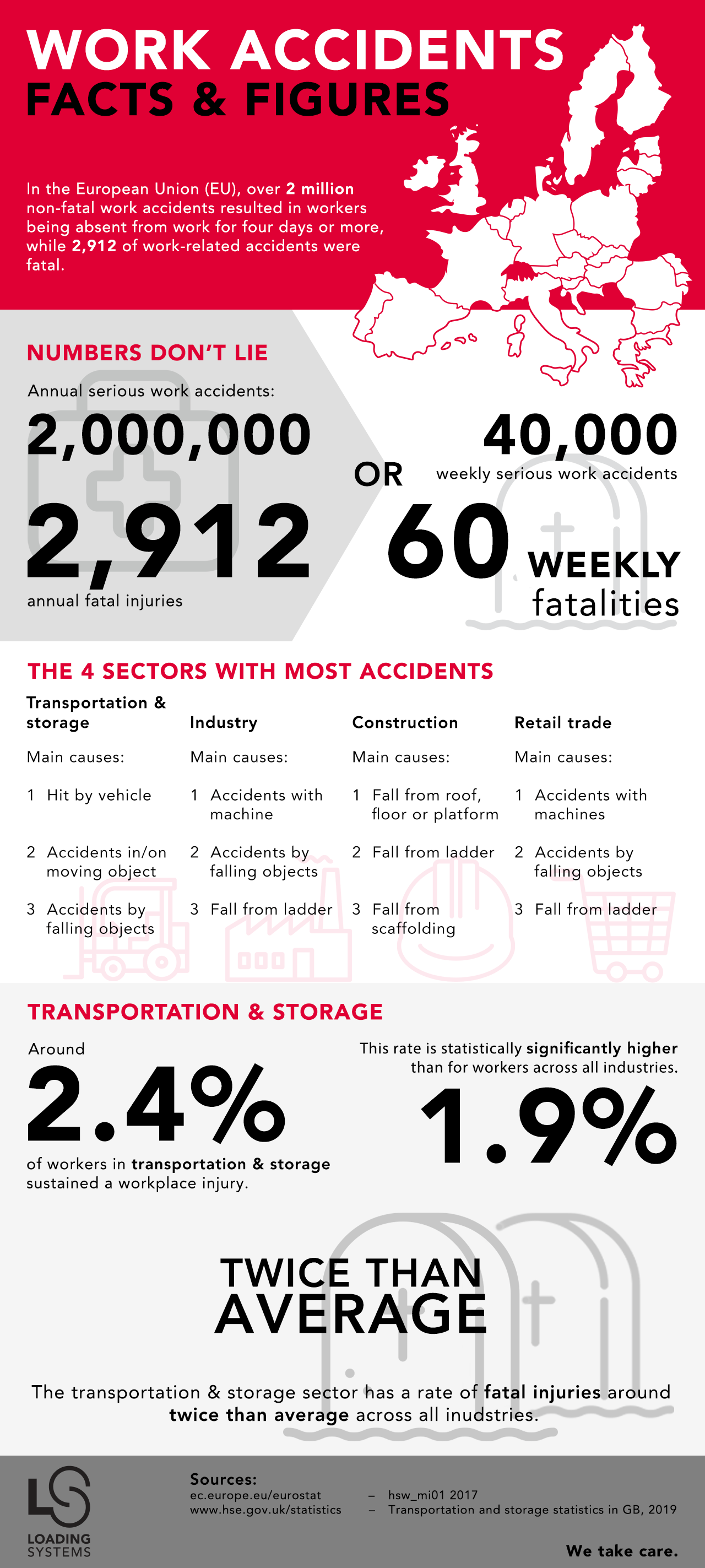

We take great measures to keep our loved ones safe. When travelling, we place our children in child seats and at home, we lock the front door and kitchen drawers. But our colleagues need to be protected from safety hazards too.

The loading bay undoubtedly remains the most dangerous part of any warehouse, with premature vehicle drive-off and creeping being the cause of countless accidents, injuries and even fatalities.

At Loading Systems, we take care of these safety risks with our vehicle restraint systems. These systems are specially developed to keep a parked vehicle safely in place and prevent premature vehicle drive-off and creeping, to ensure the safety of your colleagues at all times.